Tesla frame straightening requires specialized skills and technology due to their advanced vehicle engineering. Technicians use precision tools, data-driven methods, and robotic welding to restore structural integrity and maintain aesthetic appeal, ensuring Tesla vehicles remain safe and visually stunning after collision damage.

Tesla vehicles are renowned for their innovative design, but their frame straightening process presents unique challenges. This article delves into the intricate world of Tesla frame straightening and welding techniques. We explore the specific design considerations of Tesla frames and the specialized tools used to correct any misalignments. By understanding these processes, we uncover the precision required to maintain structural integrity, ensuring Tesla owners receive top-quality repairs.

- Understanding Tesla Frame Design and Its Unique Challenges

- The Art of Straightening: Tools and Techniques Employed

- Welding Precision: Ensuring Structural Integrity Post-Straightening

Understanding Tesla Frame Design and Its Unique Challenges

Tesla vehicles are renowned for their sleek design and advanced technology, but their frame construction presents unique challenges when it comes to straightening and welding. Unlike traditional cars, Tesla frames often feature intricate structural designs that incorporate electric motors, battery packs, and advanced drive systems, making standard frame straightening techniques less applicable. These modern vehicles demand specialized approaches to ensure precision and maintain the integrity of their innovative architecture.

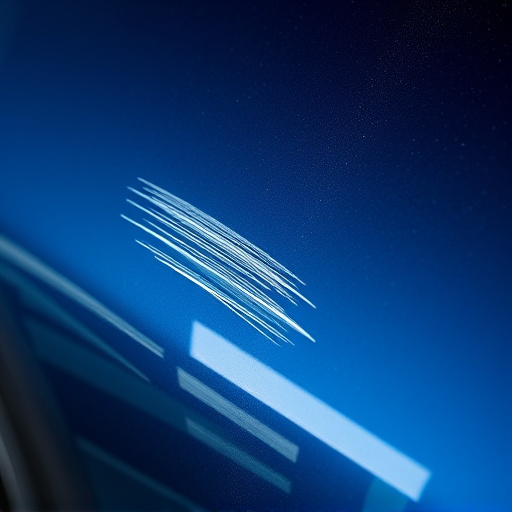

In a vehicle body shop or collision repair center, Tesla frame straightening requires a deep understanding of the car’s underbody dynamics. Technicians must carefully navigate around various components, such as high-voltage systems and complex suspension layouts, while effectively removing dents and repairing damage. The goal is to preserve the original structural integrity and aesthetic appeal without compromising Tesla’s cutting-edge engineering.

The Art of Straightening: Tools and Techniques Employed

In the realm of Tesla frame straightening, the art lies in meticulous precision and advanced techniques. Professional technicians employ a diverse array of tools to achieve perfect alignment, from specialized hydraulic presses to computer-aided measurement systems. These innovative solutions ensure that every contour and curve is restored to its original specifications, reflecting the iconic design of Tesla vehicles.

The process begins with careful assessment using high-tech scanners that detect even the slightest imperfections. This data guides the selection of appropriate straightening methods, whether it’s robotic welding for complex joins or manual manipulation for more delicate areas. The goal is not just to straighten the frame but to revive the vehicle’s structural integrity and aesthetic appeal, mirroring the meticulous craftsmanship of a premier vehicle body shop. Collision damage repair often involves these intricate techniques, transforming damaged cars into as-new masterpieces through car body restoration.

Welding Precision: Ensuring Structural Integrity Post-Straightening

Welding precision plays a pivotal role in maintaining structural integrity after Tesla frame straightening. The process involves intricate techniques to ensure that the metal bonds securely and seamlessly, preserving the vehicle’s overall stability and safety standards. Skilled technicians employ advanced welding equipment, such as laser or robot-assisted systems, to deliver accurate, consistent, and precise welds, resulting in a robust framework.

In the realm of car body shops and car restoration, achieving flawless welds is paramount. Paintless dent repair techniques complement frame straightening by minimizing damage to the vehicle’s finish. This meticulous approach not only ensures the structural soundness of the Tesla but also preserves its aesthetic appeal, making it a priority in top-tier automotive care facilities.

Tesla frame straightening is a specialized process that requires advanced techniques and precise control. By understanding the unique challenges of Tesla vehicle frames, employing state-of-the-art tools, and maintaining meticulous welding practices, professionals can restore structural integrity and ensure these electric vehicles remain safe and reliable for years to come. These techniques not only address cosmetic issues but also preserve the overall performance and value of Tesla cars, making them a top choice for repair enthusiasts and owners alike.